|

|

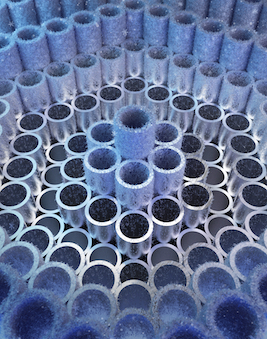

Solid state nickle titanium tubing, used in an elastocaloric prototype, supports green and efficient cooling. Image credit: Jiaqi Dai |

|

A climate-friendly and highly-efficient solid state cooling technology developed at the University of Maryland (UMD) has been named one of the top 10 breakthrough technologies of 2024 by the World Economic Forum. The technology is being developed by researchers at the A. James Clark School of Engineering’s Center for Environmental Energy Engineering (CEEE) and Department of Materials Science and Engineering (MSE).

The onslaught of scorching summer days is a reminder of the peril of global warming and climate change. Elastocaloric cooling belongs to the family of energy-efficient solid-state cooling techniques called caloric cooling. Unlike the ubiquitous vapor compression technology, which derives cooling from pressure-induced liquid to vapor phase transition of environmentally harmful hydrofluorocarbons, elastocaloric cooling utilizes solid to solid phase transitions of functional materials. Because these techniques directly tap into the first order transition of solids, they are entirely green and naturally highly efficient.

The elastocaloric cooling effect is observed in materials such as superelastic shape memory alloys, which undergo a structural phase transition upon application of mechanical stress. A major discovery which helped to kickstart the worldwide activities in the field was the experimental observation of the large elastocaloric effect in nickle titanium wires at UMD in 2012, where the temperature lift as large as 17 K was recorded.

The UMD research team is led by Ichiro Takeuchi, interim MSE chair, Reinhard Radermacher CEEE director, and Yunho Hwang, CEEE co-director. The UMD effort funded by DOE has recently led to a successful demonstration of a full elastocaloric system with a record delivered cooling power of 260 W.

“The recognition by the World Economic Forum is a strong indication that alternative cooling technologies such as elastocalorics will likely play a more and more important role in the near future,” says Radermacher, who is also Minta Martin Professor in the Department of Mechanical Engineering.

Takeuchi described the “arcs” of development paths of solid state cooling in a perspective article published in Science this month. According to the observed trend in the specific cooling power of all reported caloric devices to date, elastoclaorics has recently “come of age”: with earlier obstacles overcome, the stage is now set for scale up efforts towards commercial applications.

“It took us over 12 years to get to where we are, but like any nascent technology, sometimes it just takes time to get to a point where you can begin to size up where you are headed,” explains Takeuchi.

Related Articles:

UMD Researchers Develop New Performance Metric to Optimize Elastocaloric Cooling Systems

CEEE Research Professor Yunho Hwang to Receive Provost’s Excellence Award

Join Us for a Tour of UMD's Energy Engineering Labs

DOE Ups Its Investment in UMD to Develop Eco-Friendly Heat Pumps

CEEE Co-Director Leads Global Webinar on Advances in Low-GWP Heat Pumps

CEEE Researcher Named Finalist in UMD’s 3MT Competition

August 11, 2024

|